DMDT SW8040XHR400 RO Element

SW-8040-400 aromatic polyamide RO element is developed by DMDT for seawater desalination. This series of elements have the characteristics of low operating pressure, low equipment investment, good desalination performance and stability. This membrane elements are generally suitable for the treatment of seawater and brackish water with high concentration. It can be used for seawater desalination, desalination of brackish water with high concentration, boiler replenishment water in power plants, wastewater reuse, concentration and recovery of high value-added substances such as food and pharmaceuticals, etc.

| Model | Active Membrane Area ft2 (m2) | Permeate Flow GPD GPD (m3/day) | Salt Rejection Rate % | Feed Spacer Thickness mill |

|---|---|---|---|---|

|

SW-8040-400 |

400 (37.2) |

7500 (28.4) |

99.8 |

28 |

|

Testing Conditions |

Operating Pressure 800 psi (5.52 MPa) |

|||

| Operation Limits

& Conditions |

Maximum operating pressure | 1200 psi (8.28 MPa) | ||

| Maximum feedwater flow | 75 gpm (17 m3/h) | |||

| Maximum feedwater temperature | 45 ℃ | |||

| Maximum feedwater flow SDI15 | 5 | |||

| Allowed pH range for feedwater in operation | 2~11 | |||

| Allowed pH range for chemical cleaning | 1~13 | |||

| Maximum concentration of free chlorine | <0.1 ppm | |||

| Maximum pressure drop per element | 15 psi (0.1 MPa) | |||

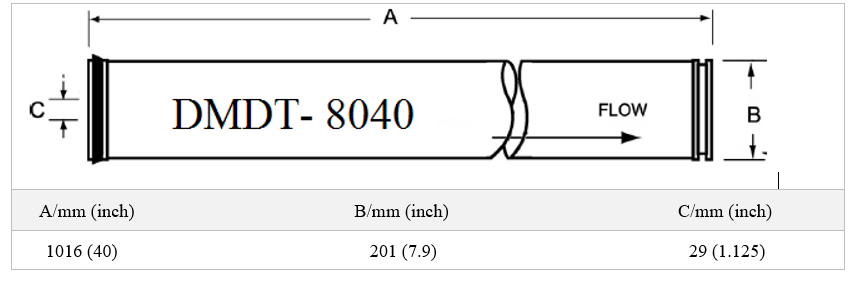

Size of Membrane Element: 1.0 inch=25.4 mm

NOTICE:

- All data and information provided in this manual have been obtained from long-term experiment by DMDT. We confirm the effective and accuracy of the data. We assume no liability for any consequences of user’s failure in abiding the conditions specified in this manual in use or maintenance of membrane products. It is strongly recommended that the user shall strictly abide the designed use and maintenance requirements and keep relevant records.

- The permeate value listed in the table is the average value. The permeate flow of single membrane element is tolerance not exceeding ±20% of the nominal value.

- All wet-type membrane elements have been strictly tested before leaving the factory, and have been treated with 1.0% sodium hydrogen sulfite (10% glycerin antifreeze required in winter) for storage purpose, then sealed with plastic bag in vacuum, and further packed in carton boxes.

- The membrane used should remain wet after being used; In long term suspension, to prevent the breeding of microbes, soak the membrane elements with protective solution is highly recommended, the solution (prepared with RO filtered water) containing 1.0% sodium hydrogen sulfite (food grade).

- Operate low pressure flushing for 15-25 minutes of first use, high pressure flushing for 60-90 minutes when first use (Permeate flow no less than 50% of designed flow). Discard all the permeate and concentrated water produced during the first one hour after system start-up.

- During storage and operation period, it is strictly prohibited to add any chemicals that may be harmful to membrane elements. In case of any violation in adding chemicals, DMDT assumes no liabilities for any damages incurred.

- Along with technical development and product renovation, all information will be subject to modification without prior notification. Please keep notice of our website for any updates of the product.